Choosing Panels and Profiles

Custom wood door design enables you to choose a theme that matches the decor of your home.

Take the time now to customize you door to achieve your desired style. We offer 4 basic panel styles, combine your choice of panels and profiles to suit your taste.

- Raised Panels are a classic choice, available in a variety of profiles.

- Shaker style Flat Panel doors are popular. Flat Panels can also be used with a profiled frame.

- Beveled Tongue and Groove Plank Panels provide a distinctive bold look.

- Square Tongue and Groove Plank Panels reflect Nautical style. Planks are gennerally narrow with 1/8" spacing.

- Our Micro-Bevel Plank is a sturdy Flush door, with a slight bevel where planks join.

Raised Panel

Flat Panel

Bevel Tongue and Groove Plank Panel

Square Tongue and Groove Plank Panel

Micro-Bevel Flush Panel

Now is the time to get creative. Take ideas from our door photo galleries, and view our standard Door Drawings..

This is a good starting point, customize your door with your desired Panels and Profiles, adding a Dentil Shelf may enhance

your door!

Frame and Panel Doors

Frame and Panel construction allows a solid wood door to remain true, even as humidity and temperature change.

Frame and Panel construction is a time honoured method, designed to enable construction of large solid wood panels (such as doors) that remain stable. The solid wood panels are free to expand and contract with humidity changes, while the overall frames size remains the same size.

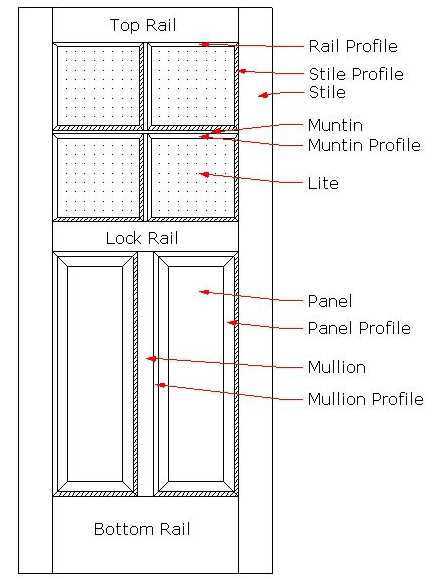

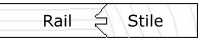

The basic Frame and Panel layout uses two vertical Stiles, and two horizontal Rails as the frame. The frame components are grooved to accept shaped Solid Wood Panels or Glass Panels.

Larger panels are usually divided using Mullions and Mid Rails.

Lites are divided using Muntins

Frame

The strength and stability of Vertical Grain Douglas Fir is unmatched for use as stile and rail

components.

The stiles and rails often have a profile cut into the inside edge - usually a

smaller version matching the profile of the panel.

The stiles and rails often have a profile cut into the inside edge - usually a

smaller version matching the profile of the panel.

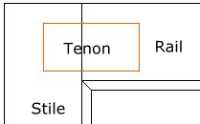

Cope and stick joinery is achieved with a set of special shaper cutters.

These cut the profile

on the edge of the frame parts and also cut a reverse version of the same profile in the ends of

the rail so that they may be fitted to the stiles and glued in place. A tenon is glued

into a precut mortise in the end of the rail and the edge of the stile, to reinforce the join.

These cut the profile

on the edge of the frame parts and also cut a reverse version of the same profile in the ends of

the rail so that they may be fitted to the stiles and glued in place. A tenon is glued

into a precut mortise in the end of the rail and the edge of the stile, to reinforce the join.

Panels

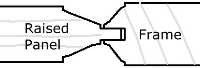

The panels are captured in a groove made in the inside edge of the frame members.

Panels are made slightly smaller than the available space within

the frame to provide room for expansion. A typical panel is cut to allow 1/8" clearance between

itself and the frame. An elastic caulking material is placed

in the groove between the edge of the panel and the frame before assembly to seal the door

against air leakage.

Panels are made slightly smaller than the available space within

the frame to provide room for expansion. A typical panel is cut to allow 1/8" clearance between

itself and the frame. An elastic caulking material is placed

in the groove between the edge of the panel and the frame before assembly to seal the door

against air leakage.

A variety of panel styles are available. Customize your door through your choice of frame profile and panel style.

To view drawings of typical door patterns, visit Door Drawings.